Needham 2 ¾" x 16" Narrow Gauge Wheel Assemblies

Needham 2 ¾” x 16” Narrow Gauge Wheel Assemblies are shipped fully assembled, ready to bolt on the drill or air-seeder. They feature TWO steel wheel halves (not one plastic and one steel like some of our competition). This is important because we have found that TWO steel wheel halves significantly outlast the steel/plastic combinations, especially when operating in hard soils or heavy residue when a lot of ballast is required to press the openers consistently into the soil. Within these conditions, it often increases the down-force on the gauge wheel assembly and this results in increased wear within plastic bearing sockets (within the wheel half of the narrow gauge wheel with the plastic wheel half). Our narrow gauge wheels also come standard with a high quality 5203 double-row ball bearing, for long service life, this is the same bearing that most manufacturers have used within gauge wheel assemblies for many years with good success. From late 2012, all our narrow gauge wheel assemblies will be shipped with NEW URETHANE TIRES. Following field testing on high acre seeding equipment across the central and northern plains over the past year, we have found that urethane tires significantly outlast our own previous rubber tires and the rubber tires installed on competitive narrow gauge wheel assemblies. The increases in service life provided by urethane tires (compared to rubber narrow gauge wheel tires) are most visible when no-tilling into short soybean stubble. Within these tough conditions, the service life of the urethane tires is estimated to be at least 3 times longer than currently available rubber narrow gauge wheel tires. There are three major benefits of Needham Narrow Gauge Wheels, these include:

Note: Narrow Gauge Wheels should be avoided in loose conventional soils (not that a no-till drill performs well in these conditions anyway) but depth control will be less desirable with a narrower wheel compared to a 4 ½" wide Gauge Wheel.

We had some of our new urethane tires out for testing during 2012. These were strategically positioned on high acreage seeding equipment and especially within high wear environments, such as growers who no-till into short soybean stubble. One narrow gauge wheel equipped with a urethane tire was sent to Joe Swanson in Windom, Kansas. Below are his texted comments regarding these new gauge wheels fitted with our new urethane tires: “Your new narrow gauge wheel tires are wearing way better than the others. There is almost 5000 acres on these tires – Very impressive !!!” 1475 acres were bean stubble ! (Photo from Joe Swanson) How Narrow Gauge Wheels Improve Depth Control.

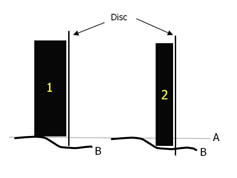

Narrow gauge wheels are very beneficial within fields with undulating soil surfaces, for example when seeding into previous equipment wheel-tracks. Wheel-tracks and other depressions in the soil surface (which run parallel to the seeding pass) frequently interfere with depth control and final seed placement. These problems are illustrated within the image to the left. Notice how the standard 4 1/2" gauge wheel (1) rides on the shoulder of a surface depression (B) which causes the disc to lose contact with the soil completely. The 2 3/4" narrow gauge wheel (2) by comparison, is better able to drop down into the same depression (B) and help the disc achieve a more consistent seeding depth to improve seed placement consistency. For more information, together with pricing – please click the link below. |

Product Guide

Product Guide